Automated Ultrasonic Testing (AUT) Services in Guyana

- June 5, 2025

- Posted by: vmsbala@gmail.com

- Category: Uncategorized

Automated Ultrasonic Testing (AUT) Services in Guyana

Delivered by Qualitest Offshore Inc.

Qualitest Offshore Inc. provides cutting-edge Automated Ultrasonic Testing (AUT) services across onshore and offshore facilities throughout Guyana. With proven experience in high-precision ultrasonic inspections, we support critical industries including oil & gas, marine, construction, and energy with advanced, reliable flaw detection on welds, pipelines, tanks, and structural components.

📡 What is Automated Ultrasonic Testing (AUT)?

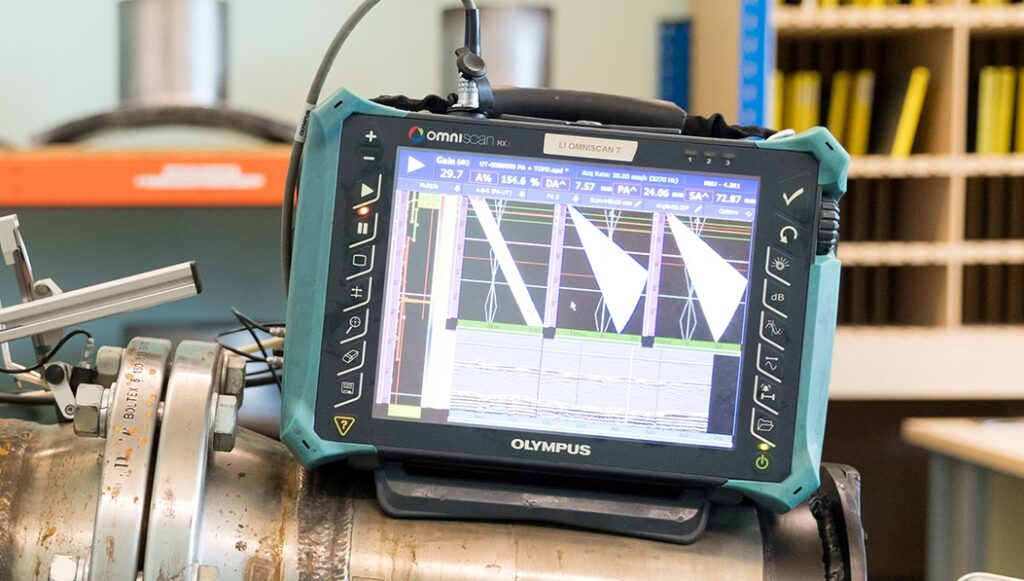

AUT is an advanced non-destructive testing (NDT) method that uses automated scanners and phased array ultrasonic transducers to detect and size internal flaws in materials. Unlike manual UT, AUT offers higher accuracy, repeatability, and data recording capabilities, making it ideal for inspecting long weld seams, pipelines, and pressure vessels—especially in high-spec environments like FPSOs and subsea systems.

⚙️ Why Choose AUT?

AUT provides distinct advantages over conventional inspection methods:

- ✔ High-speed scanning of long welds and structures

- ✔ Detailed defect characterization with depth, length, and height sizing

- ✔ Automated data collection for traceable records and advanced analysis

- ✔ Minimally intrusive—no radiation required (unlike radiography)

- ✔ Reduces downtime with faster inspections and real-time results

- ✔ Fully compliant with industry standards for critical infrastructure

In Guyana’s fast-paced offshore energy sector, AUT delivers the efficiency, accuracy, and traceability essential to safe, compliant operations.

📍 Where We Perform AUT in Guyana

Our AUT inspection services are deployed across:

- FPSOs (Floating Production Storage and Offloading vessels)

- Subsea and topside pipelines

- Onshore and offshore oil & gas facilities

- Storage tanks and pressure vessels

- Process piping and flowlines

- Fabrication yards and welding shops

🔎 Typical AUT Applications

- Long seam weld inspection (CRA-clad, carbon steel, stainless)

- Pipeline girth weld examination

- Offshore risers and spool pieces

- Structural welds on jackets, topsides, and FPSO modules

- Corrosion mapping and erosion profiling

- Heat-affected zone (HAZ) analysis

🛠️ AUT Inspection Process

1. Surface Preparation

The inspection area is cleaned and, if necessary, coated with couplant to ensure optimal sound transmission.

2. Scanner Setup

A mechanized scanner equipped with phased array probes is positioned along the inspection zone. The system is calibrated according to component geometry and material.

3. Data Acquisition

Ultrasonic waves are emitted into the material and reflected signals are captured. High-resolution data is collected and recorded in real time.

4. Data Analysis & Interpretation

Our certified AUT analysts interpret volumetric flaws, classify indications, and produce a digital report complete with C-scan, B-scan, and D-scan imaging.

5. Reporting & Recommendations

We provide a detailed inspection report with defect sizing, location, and severity—including recommendations for corrective actions, if required.

📏 Standards We Follow

Our AUT services comply with global and industry-specific standards, including:

- ASME Section V

- API 1104 & API 1169

- DNV-OS-F101

- ISO 13588 / ISO 17640

- CSA Z662 (Pipeline Integrity)

🚧 Preventing Failures with AUT

AUT allows for early detection of:

- Lack of fusion and incomplete penetration

- Cracks, porosity, and slag inclusions

- Wall loss due to corrosion or erosion

- Weld geometry anomalies

This prevents:

- Costly production delays and shutdowns

- Integrity breaches in high-pressure systems

- Safety incidents during operations or commissioning

✅ Why Choose Qualitest Offshore Inc. for AUT?

- 🧑🔧 Level II & III Certified AUT Technicians

- 🚀 Rapid mobilization across Guyana’s onshore and offshore sites

- 🖥️ High-resolution phased array and TOFD systems

- 📘 Compliance with global NDT codes

- 📊 Digitally archived inspection reports for future audits

- 🔧 Full support for welding QA/QC, commissioning, and asset integrity programs

🔧 Our Broader NDT Portfolio

We also provide:

- Phased Array Ultrasonic Testing (PAUT)

- Time of Flight Diffraction (TOFD)

- Radiographic & Manual UT

- Water Washable Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Eddy Current Testing (ECT)

- Hydrostatic & Leak Testing

- Visual Testing (VT)

- Welding Engineering & Procedure Development

📞 Schedule Your AUT Inspection Today

Ensure your pipeline welds, pressure vessels, and critical infrastructure are safe and compliant.

📧 Email: guyana@qualitest.gy

📞 Phone: +592 751 6883

Qualitest Offshore Inc. – Your trusted NDT partner in Guyana’s oil, gas, and energy industries.