Fluorescent Magnetic Particle Testing for Boiler Welds in Guyana – Reliable NDT Services

- June 11, 2025

- Posted by: vmsbala@gmail.com

- Category: Uncategorized

✅ Expert Boiler Weld Inspection in Guyana with Fluorescent Magnetic Particle Testing (FMPT)

Qualitest Offshore Inc offers advanced boiler weld inspection in Guyana using Fluorescent Magnetic Particle Testing (FMPT)—a proven non-destructive testing (NDT) technique that delivers accurate detection of surface and near-surface flaws in ferromagnetic materials.

We proudly serve industries across Guyana, Suriname, Trinidad, and Brazil, including oil and gas, power generation, marine, and heavy industry. Our inspections are designed to maximize equipment reliability, safety, and compliance with international standards.

🔍 What Is Fluorescent Magnetic Particle Testing (FMPT)?

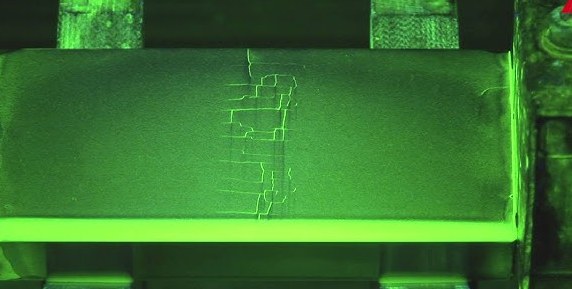

FMPT is a high-precision inspection method that uses a magnetic field and fluorescent particles to detect surface-breaking defects. Under ultraviolet (UV) light, any flaws become clearly visible with bright, glowing contrast. This method is ideal for identifying:

- Cracks

- Seams

- Cold shuts

- Laps

- Lack of fusion

- Surface porosity

Its speed, safety, and sensitivity make FMPT a preferred technique for inspecting boiler welds under high-stress conditions.

✅ Materials and Weld Types Suitable for FMPT

FMPT is applicable to a wide range of ferromagnetic components, including:

- Carbon steel and low-alloy welds

- Boiler drums and tubes

- Pressure vessel joints

- Tube-to-tube sheet connections

- Heat exchanger systems

Whether during fabrication or operational maintenance, FMPT ensures that welds meet safety codes and perform reliably under pressure.

🔧 Where FMPT Is Used in Boiler Weld Inspection

Qualitest Offshore recommends FMPT for various inspection stages:

- Boiler system commissioning

- Preventive maintenance during shutdowns

- Pressure part inspections in oil & gas plants

- Tube and header weld inspection

- Routine integrity assessments in power stations

- Structural component evaluation in marine boilers

FMPT is a fast, efficient method that helps reduce downtime and catch issues before they become critical.

⭐ Key Benefits of FMPT for Boiler Weld Testing

- ✅ Highly sensitive to surface-breaking flaws

- ✅ Quick setup and rapid inspection times

- ✅ Excellent contrast under UV for visual clarity

- ✅ Effective on complex and irregular surfaces

- ✅ Minimal surface prep required

- ✅ Radiation-free and safe for live environments

- ✅ Reports compliant with ASME, AWS, API, and ISO standards

FMPT provides real-time results that enable faster decision-making and better asset management.

🛠 Why Choose Qualitest Offshore for FMPT in Guyana?

Our inspection team includes certified experts (ASNT, PCN, ISO) with years of hands-on experience in NDT across various sectors. We use state-of-the-art UV lamps, portable magnetizing equipment, and advanced reporting tools to deliver accurate and reliable results—anywhere in Guyana and beyond.

🚀 What Makes Qualitest Offshore Stand Out?

- ✅ Certified NDT professionals with global field experience

- ✅ Cutting-edge magnetic particle testing technology

- ✅ Rapid mobilization to any location in Guyana or the Caribbean

- ✅ Deep industry knowledge in oil & gas, power, and maritime sectors

- ✅ Detailed, digital inspection reports with photo evidence and traceability

Our commitment to quality, safety, and efficiency ensures that your systems stay operational and compliant.

📅 Schedule Your Boiler Weld FMPT Inspection in Guyana Today

Need a certified team for boiler weld inspection using FMPT? Qualitest Offshore Inc delivers expert NDT solutions that ensure structural integrity and reduce risk.

📧 Email: guyana@qualitest.gy

📞 Phone: +592 751 6883

🌐 Website: https://qualitest.gy

Qualitest Offshore Inc – Your reliable partner for Fluorescent Magnetic Particle Testing and advanced boiler inspection services across Guyana, Suriname, Trinidad, and Brazil.