Chiller Tube Inspection with IRIS Technology in Guyana

- June 9, 2025

- Posted by: vmsbala@gmail.com

- Category: Uncategorized

✅ High-Precision Chiller Tube Inspection in Guyana with IRIS Technology

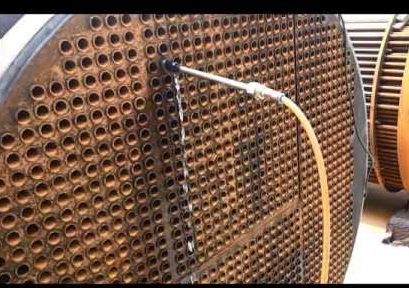

Looking for accurate chiller tube inspection in Guyana? Qualitest Offshore Inc offers expert inspection services using IRIS (Internal Rotary Inspection System) technology—one of the most reliable non-destructive testing (NDT) methods for detecting internal tube flaws with ultrasonic precision.

Our IRIS services ensure 360° tube wall thickness analysis without requiring system shutdowns or tube removal—saving your facility time and money.

We proudly serve industrial and offshore clients across Guyana, Suriname, Trinidad, and Brazil, with deep experience in the oil & gas, petrochemical, HVAC, energy, and manufacturing sectors.

🔍 What is IRIS Tube Inspection?

IRIS (Internal Rotary Inspection System) is an advanced ultrasonic NDT technique designed to detect:

- Corrosion

- Erosion

- Pitting

- Wall thinning

A water-propelled, rotating ultrasonic probe is inserted into each tube, delivering 360-degree wall thickness measurements with micron-level accuracy.

IRIS is suitable for both ferrous and non-ferrous materials, making it an essential tool for critical equipment inspection in high-risk industries.

✅ IRIS Tube Inspection Is Ideal For:

- Carbon steel tubes

- Stainless steel tubes

- Copper alloys

- Titanium and specialty metals

- Heat exchangers, condensers, and chillers

Whether it’s for a refinery or an offshore platform, IRIS ensures that every inch of your tube system is evaluated with unmatched precision.

🔧 Common Applications of IRIS in Guyana

Our IRIS chiller tube inspection services are used in:

- Commercial and industrial HVAC chillers

- Heat exchangers in power plants and refineries

- Condensers and evaporators in energy and chemical plants

- Fin-fan coolers and process chillers

- Offshore cooling units on FPSOs and oil rigs

⭐ Key Benefits of IRIS Tube Inspection Technology

- ✅ Highly accurate wall thickness measurement

- ✅ Full 360° internal coverage for reliable flaw detection

- ✅ Non-invasive and safe for scheduled or emergency inspection

- ✅ Detects corrosion, thinning, erosion, and internal damage

- ✅ Meets global NDT standards (ASNT, ISO 9712)

- ✅ Delivers detailed, digital inspection reports

- ✅ Reduces unplanned shutdowns and extends equipment lifespan

By integrating IRIS into your maintenance program, you can maximize operational efficiency and minimize risk.

🛠 Why Choose Qualitest Offshore Inc for IRIS Inspection in Guyana?

At Qualitest Offshore Inc, we combine industry-leading IRIS technology with a skilled team of ASNT- and PCN-certified NDT professionals. With a strong presence in Guyana and the wider Caribbean region, we offer rapid deployment, reliable reporting, and results you can trust.

✅ Our Strengths:

- Experienced, certified IRIS inspection technicians

- Advanced ultrasonic and data analysis equipment

- Fast mobilization across Guyana and neighboring regions

- In-depth knowledge of offshore and industrial environments

- Comprehensive reporting to guide repair and maintenance decisions

📅 Schedule Your IRIS Chiller Tube Inspection in Guyana

Ensure the efficiency and reliability of your chiller and heat exchanger systems. Partner with Qualitest Offshore Inc for accurate and professional IRIS inspection services in Guyana and across South America.

📧 Email: guyana@qualitest.gy

📞 Phone: +592 751 6883

🌐 Website: https://qualitest.gy

Qualitest Offshore Inc – Your trusted partner for IRIS-based chiller tube inspections in Guyana, Suriname, Trinidad, Brazil, and throughout the Caribbean and South America.